Introduction

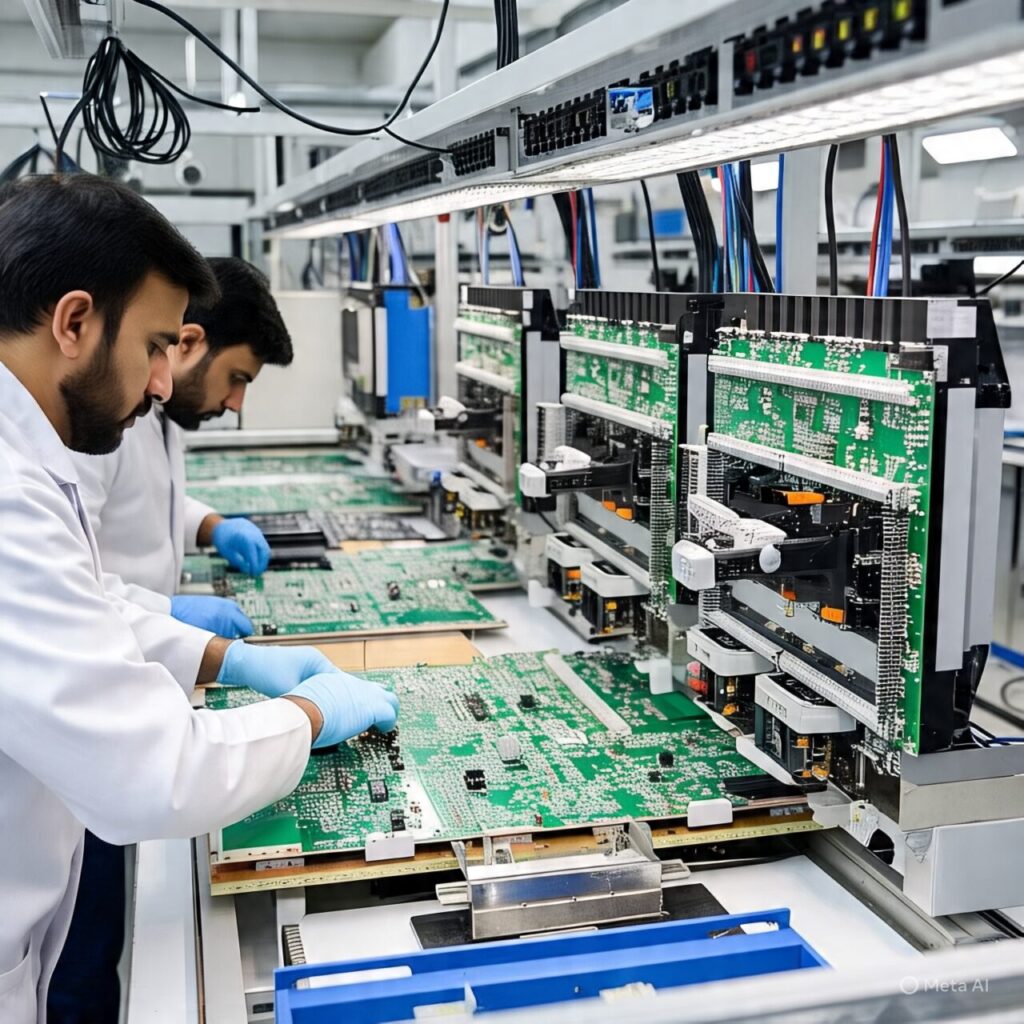

Pakistan’s electronics manufacturing sector stands at a crossroads. Companies either embrace advanced SMD (Surface Mount Device) technology or watch competitors pull ahead with faster production, lower costs, and superior product quality.

I’ve witnessed this transformation firsthand. Last month, a Karachi-based electronics manufacturer approached us after losing three major contracts. Their through-hole assembly process couldn’t compete with SMD-equipped rivals who delivered the same products 40% faster and 25% cheaper. Within six weeks of switching to professional SMD services, they not only won back those contracts but secured two additional ones.

Here’s the reality: SMD technology isn’t just about smaller components. It’s about revolutionizing how Pakistani manufacturers approach electronics production. While traditional assembly methods require extensive manual labor and lengthy production cycles, SMD services enable automated precision that transforms business economics.

The numbers tell the story. Companies partnering with professional SMD providers typically see production speeds increase by 60-80%. Component costs drop by 15-30% due to bulk sourcing capabilities. Most importantly, product reliability improves dramatically – we’re talking about failure rates dropping from 2-3% to under 0.5%.

But here’s what most manufacturers miss: choosing the wrong SMD services provider can be worse than not upgrading at all. Substandard assembly leads to field failures, warranty claims, and damaged reputations that take years to rebuild.

This guide breaks down five essential SMD services that separate industry leaders from followers. You’ll discover exactly what to look for in a provider, how to calculate ROI on SMD investments, and why timing your transition correctly can make or break your competitive position.

Whether you’re manufacturing consumer electronics, industrial controls, or telecommunications equipment, these insights will help you navigate Pakistan’s evolving electronics landscape with confidence.

Understanding SMD Technology’s 3 Core Advantages for Pakistani Manufacturers

Surface Mount Device technology has fundamentally changed how we think about electronics manufacturing. Unlike traditional through-hole components that require drilling holes and manual insertion, SMD components mount directly onto circuit board surfaces using specialized equipment and techniques.

Space Efficiency – Why Size Matters in Modern Electronics

SMD components occupy 70% less board space compared to through-hole alternatives. This isn’t just about making devices smaller – though that’s certainly important in consumer electronics. The real advantage lies in component density and functionality.

Consider smartphone manufacturers. A typical smartphone PCB contains over 1,000 individual components. Using through-hole technology, that same functionality would require a board three times larger. Pakistani manufacturers serving global markets understand this constraint intimately.

I remember working with a Lahore-based company designing LED driver circuits for international clients. Their initial through-hole design measured 4×6 inches. After transitioning to SMD components, we reduced the same circuit to 2×3 inches while actually adding more features. The client was able to fit two circuits in the same enclosure space, doubling their product performance.

Cost Reduction Through Automated Assembly Processes

Automation is where SMD technology truly shines for Pakistani manufacturers. While through-hole assembly requires skilled technicians for each placement, SMD assembly uses pick-and-place machines that can position 50,000+ components per hour with microscopic precision.

Labor costs represent 40-60% of traditional electronics assembly expenses in Pakistan. SMD automation reduces this to 15-25%, freeing up resources for research, development, and market expansion. The mathematics are compelling for any manufacturer processing more than 100 units monthly.

Enhanced Performance in High-Frequency Applications

SMD components offer superior electrical performance, particularly in high-frequency applications above 10MHz. Shorter lead lengths reduce parasitic inductance and capacitance, critical factors in modern digital circuits and RF applications.

Pakistani telecommunications equipment manufacturers have discovered this advantage when competing for 5G infrastructure contracts. SMD-based designs consistently outperform through-hole equivalents in signal integrity tests, often making the difference between winning and losing major projects.

5 Critical SMD Services Every Electronics Company Needs

The transformation from traditional assembly to SMD technology requires more than just new equipment. Success depends on partnering with providers who understand the complete ecosystem of services supporting modern electronics manufacturing.

Service #1 – Precision SMD Assembly and Placement

Professional SMD assembly goes far beyond simply placing components on boards. It requires understanding thermal profiles, solder paste properties, component orientation, and quality control at microscopic levels.

Our assembly process begins with stencil design optimization. The stencil determines how solder paste is applied to each pad, directly affecting joint quality and long-term reliability. We’ve found that 95% of assembly defects trace back to improper stencil design or paste application techniques.

Pick-and-place accuracy becomes critical with components as small as 01005 (0.4mm x 0.2mm). Our equipment maintains ±25-micron placement accuracy – roughly one-third the width of human hair. This precision ensures consistent electrical connections and prevents component shifting during reflow soldering.

Temperature profiling represents another crucial aspect often overlooked by inexperienced providers. Each PCB design requires a unique thermal profile balancing component survival with solder joint formation. We monitor reflow temperatures at 8+ points across every board, adjusting profiles based on component thermal mass and board complexity.

Service #2 – Advanced SMD Component Sourcing and Procurement

Component sourcing has become increasingly complex as global supply chains face disruptions and counterfeit components flood secondary markets. Professional SMD providers maintain relationships with authorized distributors and implement rigorous component authentication processes.

A Rawalpindi manufacturer learned this lesson expensively last year. They sourced “equivalent” microcontrollers from an unauthorized supplier to save 15% on component costs. Six months later, field failures began appearing due to counterfeit chips with substandard specifications. The recall cost exceeded their annual profit margin.

Our procurement team maintains accounts with over 50 authorized distributors globally, ensuring component authenticity and traceability. We also provide component lifecycle management, alerting clients to obsolescence issues 12-18 months before end-of-life announcements from manufacturers.

Inventory management becomes crucial for maintaining production schedules. We maintain safety stock for critical components and provide just-in-time delivery for standard items, reducing our clients’ working capital requirements by 25-40%.

Service #3 – Quality Control Through AOI and X-Ray Inspection

Visual inspection alone cannot guarantee SMD assembly quality. Components hidden under other parts, microscopic solder joints, and internal connection integrity require advanced inspection techniques.

Automated Optical Inspection (AOI) systems examine every solder joint using high-resolution cameras and pattern recognition algorithms. Our AOI equipment identifies defects as small as 25 microns – problems invisible to human inspectors even under magnification.

X-ray inspection reveals issues that AOI cannot detect: voids in solder joints, shorts between layers in multilayer boards, and component placement accuracy under larger parts like QFP packages. We perform X-ray inspection on 100% of assemblies containing BGA (Ball Grid Array) components where solder joints remain hidden beneath the component body.

Statistical process control helps identify trends before they become problems. We track defect rates, placement accuracy, and solder joint quality across production runs, adjusting processes proactively rather than reactively addressing failures.

Service #4 – Professional SMD Rework and Repair Solutions

Even with perfect processes, electronics manufacturing occasionally requires rework and repair services. SMD rework demands specialized equipment and expertise to avoid damaging surrounding components or PCB traces.

Hot air rework stations provide controlled heating for component removal and replacement. Our technicians use customized nozzles and temperature profiles for each component type, ensuring thermal damage prevention while achieving reliable solder joint formation.

Component-level troubleshooting often reveals design issues that prevent successful assembly. We provide engineering feedback to help clients optimize designs for manufacturability, reducing rework requirements in future production runs.

Board-level repair services extend product lifecycles and reduce warranty costs. Rather than scrapping assemblies with single component failures, professional rework can restore full functionality at 20-30% of replacement cost.

Service #5 – Custom SMD Design and Prototyping Support

Many Pakistani manufacturers lack internal engineering resources for optimal SMD design implementation. Professional providers offer design review services, component selection guidance, and prototype development support.

Design for manufacturability (DFM) analysis identifies potential assembly issues before production begins. Common problems include inadequate component spacing, thermal management challenges, and test point accessibility. Addressing these issues in design phases costs far less than correcting them during production.

Prototype development allows testing and refinement before committing to full production. We provide rapid prototyping services with 5-7 day turnaround times, enabling faster product development cycles and reduced time-to-market.

Component selection optimization balances performance requirements with cost constraints and availability considerations. Our engineering team maintains current knowledge of component trends, helping clients avoid obsolescence issues and optimize bill-of-materials costs.

How Pakistani Companies Benefit from Partnering with Expert SMD Providers

The decision to outsource SMD services versus building internal capabilities represents a strategic choice affecting competitiveness, cash flow, and growth potential. Most successful Pakistani electronics companies have discovered that partnership models offer superior returns compared to internal investment.

4 Ways Professional SMD Services Reduce Production Costs

Cost reduction extends far beyond simple labor savings. Professional SMD providers deliver economies of scale, equipment utilization efficiency, and process optimization that individual manufacturers cannot achieve independently.

Equipment amortization costs become manageable when shared across multiple clients. A complete SMD assembly line requires $500,000-$2,000,000 investment depending on capability levels. Professional providers spread these costs across higher production volumes, reducing per-unit equipment costs by 60-80% compared to dedicated internal lines.

Component purchasing power generates significant savings through volume discounts and distributor relationships. Our purchasing volumes enable 10-25% component cost reductions compared to individual manufacturer purchases. For products with high component costs, this advantage alone justifies outsourcing decisions.

Quality improvements reduce warranty costs and field service expenses. Professional providers typically achieve 0.1-0.5% defect rates compared to 1-3% rates common with internal assembly operations. For products with high warranty costs, quality improvements provide measurable bottom-line benefits.

Process efficiency optimization reduces manufacturing cycle times and improves asset utilization. Our standardized processes and experienced operators achieve 40-60% higher throughput rates compared to companies learning SMD assembly internally.

3 Quality Standards That Separate Premium SMD Providers

Quality standards provide objective measures for evaluating SMD service providers. However, certifications alone don’t guarantee performance – implementation depth and continuous improvement processes matter more than certificates on walls.

ISO 9001:2015 certification demonstrates systematic quality management approaches. Look for providers who can explain their quality systems in practical terms rather than simply displaying certificates. Ask specific questions about corrective action processes, supplier qualification procedures, and customer feedback integration.

IPC-A-610 acceptability standards define workmanship criteria for electronic assemblies. Premium providers train all operators to IPC standards and maintain current certifications. However, the best providers exceed minimum IPC requirements, implementing additional quality controls based on application-specific needs.

Statistical process control implementation reveals providers committed to continuous improvement. Ask to see control charts, defect trending data, and process capability studies. Providers who cannot produce this information likely lack systematic quality approaches despite holding relevant certifications.

Timeline Advantages – From Concept to Market in 8 Weeks

Time-to-market advantages can determine product success in competitive electronics markets. Professional SMD providers maintain inventory, equipment, and processes that dramatically reduce development and production timelines.

Prototype development timelines compress from weeks to days when working with experienced providers. Our prototype services typically deliver first articles within 5-7 days of design finalization, compared to 3-4 weeks required for internal prototype development.

Production scalability becomes seamless with established SMD providers. We can scale from prototype quantities to thousands of units without retooling or process changes. Internal operations often require weeks or months to scale production after prototype completion.

Supply chain integration accelerates component procurement and reduces inventory requirements. Our established supplier relationships and inventory management systems ensure component availability without requiring client investment in purchasing departments or inventory carrying costs.

Choosing Your SMD Services Partner – 6 Essential Criteria

Selecting the right SMD services provider affects product quality, production costs, and competitive positioning for years. The decision requires evaluating technical capabilities, business stability, and cultural fit factors that determine long-term partnership success.

Technical Capabilities and Equipment Standards

Modern SMD assembly requires sophisticated equipment operating within tight tolerances. Evaluate potential providers based on equipment capabilities, maintenance practices, and technology refresh policies rather than simply counting machines.

Pick-and-place equipment specifications directly affect assembly quality and production efficiency. Look for machines capable of ±25-micron placement accuracy with component sizes down to 01005. Ask about machine utilization rates, maintenance schedules, and backup equipment availability.

Inspection equipment capabilities determine defect detection rates and quality assurance effectiveness. AOI systems should provide resolution sufficient for your smallest components with false-positive rates below 2%. X-ray inspection becomes essential for BGA components and complex assemblies.

Process control systems enable consistency and traceability across production runs. Professional providers maintain detailed records of placement accuracy, reflow profiles, and inspection results for every assembly. This data enables process optimization and provides traceability for quality investigations.

Industry Experience in Pakistani Electronics Market

Local market experience provides understanding of regulatory requirements, supply chain challenges, and customer expectations specific to Pakistani electronics manufacturers. International experience alone may not translate to local market success.

Regulatory compliance knowledge becomes crucial for products destined for export markets. Experienced providers understand CE marking requirements, FCC certification processes, and other international standards affecting Pakistani electronics exports.

Supply chain management expertise helps navigate import duties, customs procedures, and local sourcing opportunities. Providers with established local supplier networks can often provide cost advantages and delivery flexibility.

Customer reference verification provides insights into provider performance under real-world conditions. Ask for references from companies manufacturing similar products or serving similar markets. Follow up with detailed questions about quality, delivery performance, and problem resolution capabilities.

Quality Certifications and Compliance Records

Quality certifications provide baseline assurance of systematic approaches to process control and customer satisfaction. However, implementation depth and continuous improvement practices matter more than certificate collections.

Audit histories reveal provider commitment to quality maintenance over time. Request copies of recent audit reports and corrective action responses. Look for providers who view audits as improvement opportunities rather than compliance burdens.

Customer complaint handling processes indicate provider responsiveness to quality issues and service problems. Ask about complaint resolution procedures, average response times, and customer satisfaction measurement systems.

Continuous improvement initiatives demonstrate provider commitment to evolving capabilities and quality enhancement. Look for evidence of process improvements, equipment upgrades, and capability expansions based on customer feedback and market requirements.

Future-Proofing Your Electronics Business with Strategic SMD Services

Electronics manufacturing continues evolving rapidly as new technologies, materials, and market requirements emerge. Strategic SMD service partnerships provide access to capabilities and expertise that enable adaptation to changing market conditions.

5 Emerging Technologies Requiring Advanced SMD Solutions

Technology evolution drives requirements for increasingly sophisticated SMD capabilities. Understanding emerging trends helps evaluate provider readiness for future challenges and opportunities.

5G electronics demand high-frequency performance optimization and thermal management capabilities beyond traditional SMD requirements. Components operate at frequencies where parasitic effects become critical, requiring specialized design and assembly techniques.

Internet of Things (IoT) devices require ultra-miniaturization and power optimization that pushes SMD technology to physical limits. 01005 components and chip-scale packages become standard rather than exotic options.

Automotive electronics adoption accelerates requirements for high-reliability assembly processes and harsh environment survival. Automotive-grade components and assembly standards exceed traditional commercial electronics requirements.

Artificial intelligence hardware requires high-performance computing capabilities and advanced thermal management solutions. BGA packages with 1000+ pins become routine rather than exceptional challenges.

Flexible electronics create entirely new assembly challenges as traditional rigid PCB assumptions no longer apply. Roll-to-roll processing and conformable assemblies require specialized equipment and processes.

Investment ROI – What to Expect in Year 1 vs Year 3

SMD service partnerships provide measurable returns that compound over time as production volumes increase and process optimization continues. Understanding realistic ROI timelines helps set appropriate expectations and measure success.

Year 1 benefits typically focus on cost reduction and quality improvement as production transitions from internal or alternative providers. Companies usually achieve 15-25% cost reductions and 50-75% quality improvements within the first production year.

Year 2 expansion often includes design optimization and process refinement that deliver additional cost savings and performance improvements. Design for manufacturability feedback and component selection optimization typically provide another 10-15% cost reduction.

Year 3 strategic benefits emerge as partnership maturity enables new product development acceleration and market expansion opportunities. Established relationships provide competitive advantages in time-to-market and capability access that compound over time.

The relationship between Pakistani electronics manufacturers and professional SMD service providers has evolved from simple outsourcing to strategic partnership. Companies that recognize this evolution and choose partners accordingly will maintain competitive advantages as the electronics industry continues its rapid transformation.

Success in Pakistan’s growing electronics market increasingly depends on accessing world-class SMD capabilities without the capital investment and learning curve required for internal development. The manufacturers who thrive over the next decade will be those who focus on their core competencies while partnering with specialists for advanced manufacturing technologies.

For more information about IPC standards for SMD assembly and Pakistan’s electronics industry growth statistics, explore these authoritative resources that provide deeper technical and market insights.